Facility status

We will support customers' green management and take the lead in

solving environmental pollution problems by recycling waste resources.

Facility status

We will support customers' green management and take the lead in

solving environmental pollution problems by recycling waste resources.

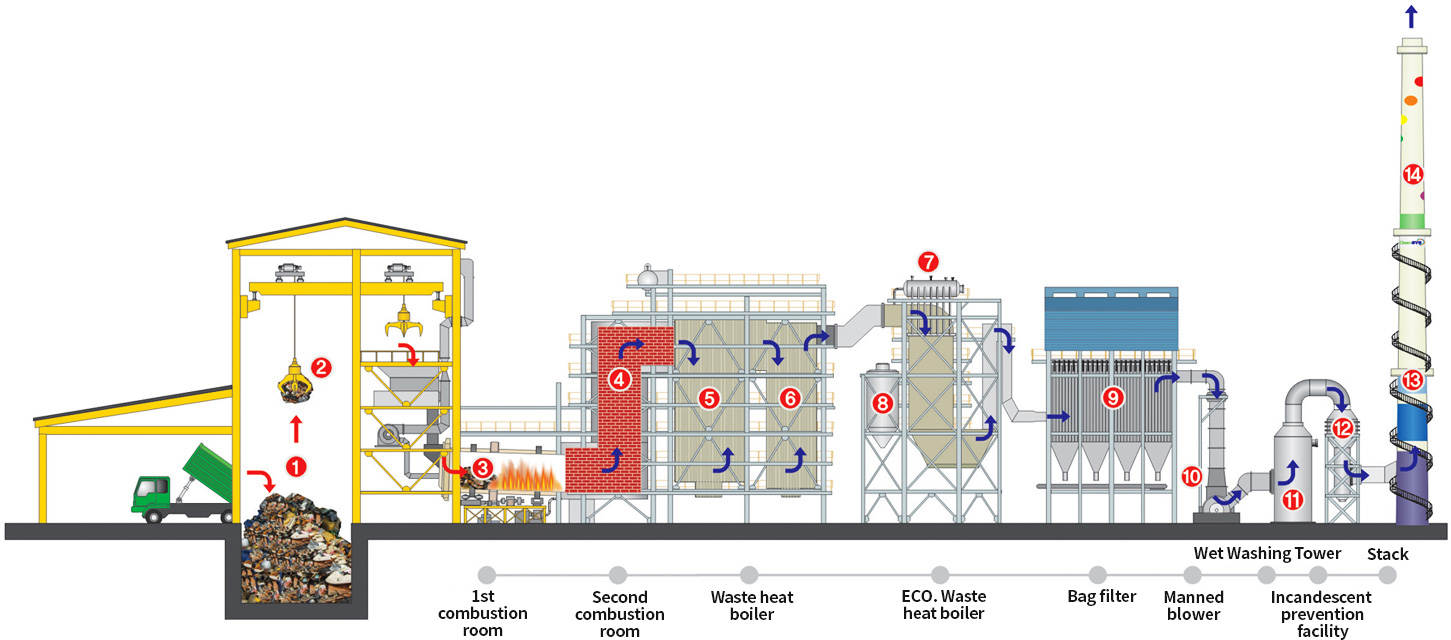

Carry-in supply facility

Rotary kiln type incineration plant

Waste heat boiler recovery facility

Air pollution prevention equipment

Waste pit

crane

Rotary kiln

Second combustion room

SNCR (catalytic denitrification facility)

Waste heat recovery boiler

ECO. Waste heat boiler

Highly reactive slaked lime and activated carbon injection facility

Filter dust collection facility

Manned blower

Wet cleaning facility

Steam reheater

T.M.S

Stack

Waste disposal

The waste carried by the collection vehicle is weighed, sorted, and stored in the storage pit. This waste is transferred to the input hopper by the overhead crane, and then put into the incinerator for combustion.

Combustion air supply

The air required for incineration of waste is sucked from the waste loading and storage tank to the primary air blower and is fed into the lower part of the incinerator to be used for drying and combustion of waste, and the secondary air blower is also used for complete combustion of unburned gas.

Flue gas flow

The high-temperature combustion gas discharged from the incineration facility is cooled to an appropriate temperature by a waste heat boiler, passes through a bag filter and scrubber, which are air pollution prevention facilities, and is discharged to the atmosphere through a chimney.

Incineration residue treatment

Incineration residues generated after incineration are classified into incineration ash and fly ash, and the incineration ash is discharged through the lower conveyor and temporarily stored in the ash storage bunker, and the fly ash contained in the combustion gas is collected and processed by a filter dust collector. Landfill treatment is carried out in a managed landfill facility accordingly.